Master computer UniCAM.10 in high demand

Just one year after the market launch of the UniCAM.10, the latest version of the master computer developed for precast concrete plants, Unitechnik records a high demand for the automation solution. Up to now, the company has sold 19 master computers all over the world, 19 of them in Germany, three in China, two in Belgium and Austria as well as one each in Italy, France, and Thailand (as at 01/16/2018). The leading manufacturers of precast concrete elements in Germany have already decided to use the new technology. The software digitally links, controls and monitors all operating processes in the precast concrete plants, thus contributing to the practical implementation of industry 4.0. Unitechnik is constantly working on the further development of the scope of functions. In future, it will be possible, for example, to retrieve production data via an app from all over the world.

A reason for the great success of UniCAM.10: The solution combines the ergonomics of a modern software design with intelligent algorithms. This results in more efficiency in the production process of precast concrete elements. The use of the master computer improves numerous operating processes significantly. „In particular, the new function for the homogenization of cycle times is very popular among our customers because it has a large influence on the productivity of precast concrete plants,“ explains Christian Mertens, sales manager of production automation at Unitechnik.

Pallet assignment improved by up to 20 %

The function allows for a uniform pallet flow through the plant, avoiding any idle time at the separate work stations. Therefore, a similar time for processing the pallets at the separate stations is an important requirement. This is achieved, among others, by an intelligent mix of several orders. To obtain maximum transparency in the production process, the disposable time for processing a pallet can be displayed on the screens at the machines. If the required working time exceeds the cycle time of the plant, a red lamp lights up. This enables the production manager to require additional personnel even before a congestion occurs at a machine. In this way, agreed-upon production targets can be met reliably.

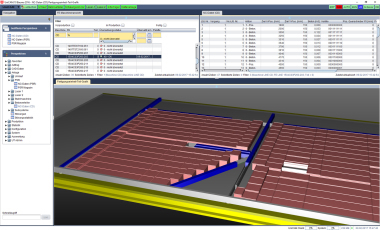

The new assignment algorithm, as an optimization function, improves the arrangement of the precast concrete elements to be produced on the production pallets. At the same time, UniCAM.10 ensures that the minimum clearances required between the elements are kept. The degree of utilization of the pallet space is improved by the algorithm by 10 to 20 %. The users increase the production capacity of their plants simultaneously.

Quality assurance in production engineering

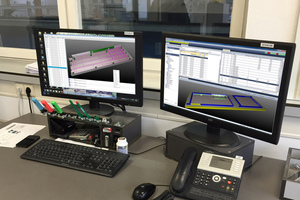

Another special feature of the master computer: According to the information given by the provider, the sytem is the only one available in the precast concrete market at present being furnished with a fully integrated laser projection system. This system enables parts to be placed on the pallet with dimensional accuracy and serves for the purpose of quality assurance. The laser is able to adapt to the individual production process.For an optimum production preparation, Unitechnik offers the UniCADViewer as add-on to the master computer. This program module enables the users to check the feasibility of orders prior to the start of production. For this purpose, any element can be visualized in a 2D and 3D presentation for examining potential defects.

Afterwards, any necessary adjustments are made by the works in the CAD system or by means of the integrated editor in the CAD-CAM data directly. The release for production is granted only thereafter. This leads to a higher production quality and prevents production rejects. In addition, the CAD viewer allows checking whether the essential production requirements are met, for example, the concrete mix design or the reinforcing steel. The CAD viewer has the same graphical user interface as the master computer. In this way, the use is possible without any additional training.

Ease of use

Apart from the economic benefit, an ergonomic and intuitive usability is an important factor of a modern production control system. Therefore, Unitechnik attached great importance to an appealing graphic design when developing the UniCAM.10. Hence, users can arrange all elements of the user interface on the display according to their own requirements or can change the size. In every window the user can show or hide fields, so that he only gets the information he really needs for his tasks. A sidebar, which is permanently visible, shows important information about the production status.

Every user, moreover, has the opportunity to use UniCAM.10 in the language preferred by him. If a language requested is not yet included in the scope of function, it will be provided by Unitechnik in the short run. The connection of mobile devices facilitates working with the master computer even outside the control center. The function of visualization with infinite zoom supports troubleshooting. Users may immerse into the plant layout down to the level of the limit switch and identify failures quickly.

Continuous further development

For the time being, the company is working on a master computer app retrieving production data from all over the world. For this purpose, the information is recorded in a cloud and the data are hosted in German computing centers. The app serves above all to recall current status information from the production, the degree of utilization of the plant, the number of square meters produced or the status of an order, for example. Plant managers can give their customers feedback about the current processing progress of an order, at any time and anywhere.

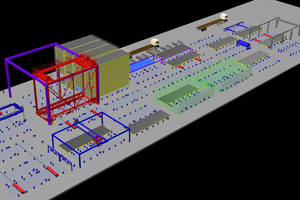

Another new feature is the add-on for plant simulation. This feature allows the user to design a new plant virtually or to simulate optimizations of existing facilities. In this way, it could be tested in advance, for example, whether the implementation of an additional work station would pay off as well as its impact on the overall pallet flow.