Large-dimensioned and precast façade elements

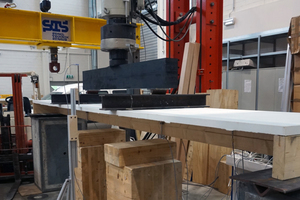

In recent years, so-called textile concretes have been used as façade elements. Stitched textile fabrics – for the most part manufactured from alkali-resistant glass fibers, carbon fibers, or amid fibers – serve as reinforcement for these building components. Wood-textile concrete composite systems that exploit the advantages of the composite action of the different materials used are another relatively recently developed construction method. An R&D project, which combines both construction techniques, has been conducted by the Laboratory for Wood Construction at the RheinMain University of Applied Sciences, and in collaboration with the engineering firm Hemmerlein Ingenieurbau GmbH. The objective was to develop a large-dimensioned, lightweight façade element in a wood-concrete construction composite without steel components.

The R&D project was supported by the German Federal Ministry for Economic Affairs and Energy within the scope of the Central Innovation Program for SMEs (ZIM). The idea of the project was to reduce the concrete cover required for protecting the steel from corrosion, enabling the creation of very slender, light, and consequently cost-efficient concrete façade elements. In order to ensure great loadbearing capacity and stiffness, despite the slight thickness, these thin plates were designed to be used in combination with wood. Towards this end, textile fabrics made of glass and/or carbon fibers were used for the first time to serve both as a mechanical means of connection in the shear joints at the interface between wood and concrete, and as reinforcement in the concrete slab.

The design of the WCC façade elements was meant to reduce the load of the structural system compared to other concrete façade panels of comparable size. For the WCC façade elements – which determine the building’s overall visual appearance, a self-compacting concrete was developed that enabled casting of the concrete into the slender, reinforced structural components. For the connection between wood and concrete, a stitched textile fabric with alkali-resistant glass fibers was used. The large-dimensioned precast façade elements, have widths of approx. 2.5 m and lengths of 4.9 m. Three ribs are laid in parallel on a slab 2.5 m wide.