Innovation: Counterflow intensive mixer

Recent years have seen continuous development of new high-performance concretes with special properties for a great number and variety of applications. The principal distinctions between these and normal concrete are their different material compositions, especially their fine contents and extremely low water/binder ratios. In addition, they possess other rheological fresh-concrete properties: for example, a self-flowing, honey-like glutinous consistency.

The innovative nature of the newly developed “Mixing device and mixing process” (GIM), for which a patent has been applied, consists of their effective satisfaction of the very special technical requirements of modern high-performance concretes and mortar. This innovation also enables the greatly varying quantities and states of aggregation of the individual components present to be distributed as rapidly and as homogeneously as possible into the overall mix.

The new process ensures colloidal dispersion of the liquid and powdered mix constituents, as well as the finest possible distribution of small and minute quantities.

In the first step, the counterflow intensive mixer produces a homogenous, colloidally dispersed binder paste from the mixing water, the superplasticizer, the powdered binders, and the additions. Immediately afterward, the additional coarse and/or fibrous constituents of the mix are dosed with the minimum possible input of energy into the mixer, stirred into the paste already prepared, and processed to produce an absolutely homogeneous mix, ready for use.

The GIM in brief

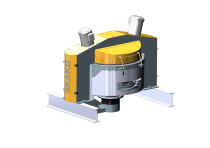

The innovative MAT system developed jointly with the company E&K-Mischtechnik Manfred Kleimeier is subdivided into two mixing zones, arranged one over the other, with different functions and different useful volumes. The mixing container (preliminary mixing zone) and the mixing trough (intensive mixing zone) were designed in U-shape, arranged in parallel on top of each other, and are tightly interconnected. The two zones are physically separated from each other by partition sheet metal provided with the required openings.

The various mixing tools rotating in the mixing container and the mixing trough are designed to achieve homogenization (in the preliminary mixing zone) and colloidal dispersion (in the intensive mixing zone) of the individual mix constituents, as well as continuous circulating exchange of the mix between the two zones.

A colloidally dispersed binder paste is initially prepared at high rotational speed from the liquid phase and the powdered constituents. During feed of the additional, coarse and/or fibrous constituents, the friction in the mix increases, accompanied by an increase in torque. The turning speed is automatically reduced. The aggregate is accordingly gently stirred into the previously prepared paste without unnecessary energy input and is processed to highly homogeneous ready-mix within a very brief time.