Determination of exposure classes in the field of wastewater and the resulting concrete cover for reinforced concrete pipes

Preliminary note

Sometimes, there is an impression of uncertainty among clients and contracting parties about the requirements to impose on concrete and in particular on the concrete cover for reinforced concrete pipes. To be on the safe side, they set excessive requirements which, however, may be detrimental at another point.

Which exposure classes are to be set for the interior and exterior of pipes?

DIN 4030-1 applies to the exterior of pipes and is relating to the soil and the groundwater. The exposure is classified into XA1 up to XA3. One problem for tendering here is the fact that the former designation “strong attack” used for XA2 now applies to XA3.

DWA-M 168 specifies values for the stress inside the pipe and stipulates which stress may occur permanently, temporarily and momentarily. It also has to be considered that discharging a medium with values above the ones proposed according to DWA-M 115-2 may lead to health hazards, apart from a possible attack on the pipe material and/or a reduced effectiveness of the wastewater treatment plant.

Normally, concrete is not able to resist an attack of biogenic sulfuric acid with a very low pH value, hence protection measures are needed. Biogenic sulfuric acid, however, is also dangerous for people and it disturbs the treatment process.

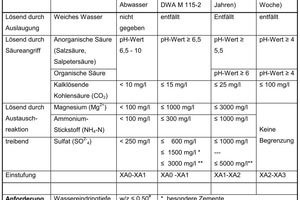

Table 1 gives a summary of the possible stress occurring in the field of wastewater.

Reinforcement corrosion can be caused by a chloride attack and by depassivation due to carbonation.

The limitation of the chloride content in usual municipal wastewater is stipulated at 250 mg/l, which means that chloride-induced reinforcement corrosion is not possible in case of unaffected concrete. The co-author has already carried out several extensive investigations on manholes used in road construction, which did not reveal increased levels of chloride contamination.

The highest exposure class XC4 (cyclic wet and dry) for carbonation requires cmin of 25 mm using C 25/30. However, carbonation is very slow in damp climate.

Abrasion stress according to XM2 can be caused by steep gradients and possible bottom load. According to DIN V 1201 the re-

sistance of a C40/50 concrete is appropriate for a flow rate of < 10 m/s.

What can the concrete of pipes set against this?

In principle, the concrete quality used for pipes and manholes of type II (FBS) in accordance with DIN V 1201 is at least C40/50 concrete. In compliance with DIN EN 1916 and/or 1917, the w/b ratio is maximum 0.45. This fulfils all requirements for XA1/XA2 as well as SM2, XD3 and XF3. The requirement specified for XA3 cannot be met by concrete permanently, but need additional protection measures (see DIN 1045-2/5.3.2). However, high-performance concrete is able to resist an attack beyond XA2, if applicable.

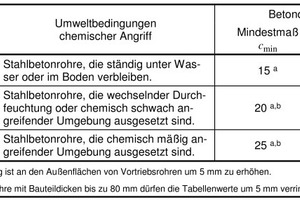

Owing to the high concrete quality required for pipes of type 2 according to DIN V 1201 and the monitored production process, the concrete cover can be slightly reduced as compared to DIN EN 206 (Tab.11 of DIN V 1201 – Table 2).

In special cases – in case of stagnant groundwater with aggressive substances or in case of abrasion, for example, – it is possible to include a so-called sacrificial layer.

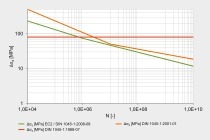

Besides the general approaches in regard to the concrete composition and the concrete cover, an even more precise assessment of the corrosion risk in particular cases can probabilistically be provided by a model for simulating the damage progress.

Determination of the concrete cover required

As far as calls for tenders are concerned, it is important that either realistic exposure classes are given and/or the requested concrete cover is defined properly. In this regard, priority has to be given to the respective product standard as opposed to a general standard.

The cnom value is relevant for the production process and the static calculation. It consists of cmin and an allowance. An allowance of 10 mm (instead of 15 mm generally) is considered to be appropriate for pipes, for example. The concrete quality can also have an influence on cmin.

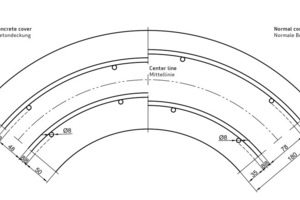

First of all, the concrete cover for usual wall thicknesses should be observed at all. Figure 1 shows the possible consequences if the concrete cover is chosen too large. There has to be sufficient space in case of two reinforcement layers for not disturbing the concrete placing process and the compaction. A too large edge distance – also in relation to the wall thickness – results in an increased crack susceptibility, because the reinforcement slowing down the crack is too far away from the tension zone. In case of pipes with single-layer reinforcement a too high concrete cover can lead to the fact that the reinforcement is placed in the compression zone in the non-cracked state I and that it is hardly effective.

Summary

A realistic assessment of the relevant exposure classes is important to ensure a safe and economical tendering procedure. Requiring a too high concrete cover may have negative effects.