Control engineering modernized

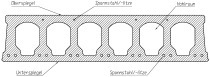

Elbe Decken, with 20 production lanes, a storage capacity over more than 45,000 m2 and an annual production capacity of 500,000 m2, is one of Germany’s leading suppliers of precast prestressed concrete for floor slabs. In production of these products, various concrete quantities are needed at various times in the plant. The automated mixing plants must precisely determine the specific concrete quantities and their consistencies that must be made available at a given production site.

In addition, the concrete mixes from Elbe must meet the exacting quality requirements of laboratory concrete. For this reason, Elbe decided at the beginning of this year to optimize its processes by modernizing the two mixing plants commissioned in 1995. This measure required an exchange of the control engineering for precast prestressed floor slab production and for mixing the various concrete mix formulations. The contract for programming and implementing the new control engineering was awarded the Unitechnik Group.

Mixing process optimized

To optimize the mixing process at Elbe and to ensure constant ongoing high quality in the future, Unitechnik exchanged the S5 control system from Siemens for an S7 version, and integrated WinCC into the higher-ranking system as new process control. In programming the process control system, automation specialists integrated all processes required for prestressed precast floor slab production, including mix formulation management, stockkeeping, as well as visualization with malfunction reporting.

In addition, man-machine-interface systems were employed in the area of mix control; the staff working in plant production can use their panels to call up and monitor processes. This enables highly detailed monitoring of production and quick intervention in an emergency situation. To ensure precise composition of the various concrete mixes, Unitechnik installed sensor-controlled moisture regulation and new weighing technology in the system. Modernization

within five days

Because production downtimes were required to be kept to a minimum, all measures had to be carried out within five days between, Christmas and the new year. “In modernizing the concrete mixers, Unitechnik has surpassed our expectations. The exchange of the control units and integration of the new process control system resulted in optimization of our mixing process and reduced concrete waste by up to 9 %,” declared Thomas Münzberg, Plant Manager at Elbe Decken. “At the same time, we profit from simple operator handling and the large scope of functions of the new control system.”