3D biaxial textile reinforcement

Textile in concrete has a great future. The most significant advantages of textile reinforced concrete are its significantly lower net weight and the ability to manufacture essentially thinner construction elements.

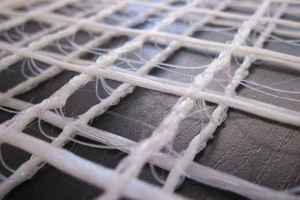

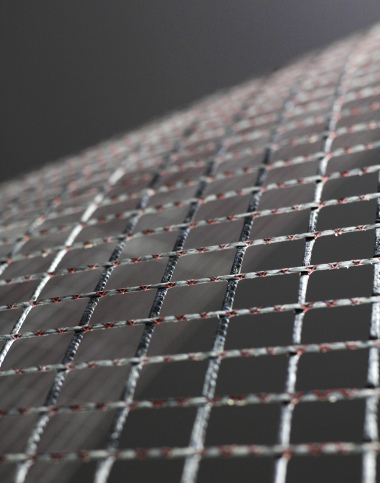

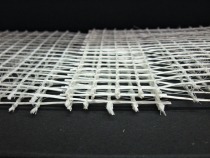

The company V. Fraas Solutions in Textile GmbH has developed an innovative textile reinforcement in its 3D textile Sitgrid which is based on a new type of knitting process. The special advantage for the manufacturing of precast concrete elements is evident in the reduction of steps in the process of casting the concrete and applying the textile reinforcement. In comparison to 2D textile reinforcement in multiple layers a more exact spacing of the two non-compressible joined layers of the 3D textiles can be achieved.

Main area reinforcement for the precast concrete industry

The main area of application for three-dimensional biaxial technical textiles is the reinforcement of precast concrete elements. Sitgrid by V. Fraas Solutions in Textile GmbH is a new type of technical textile in which two layers of textiles are joined together by a pile spacer thread into a 3D textile structure. A special advantage in the use of 3D textiles for reinforcement instead of single textile layers is evident in the quicker and safer processing: previously, additional processing steps were required for a two layer reinforcement. The 3D textile reinforcement can be applied in a single process and therefore requires fewer casting steps. The non-compressible structure of the 3D textile prevents the dislocation of the two reinforcing layers during the compaction process. It is possible to position the layers exactly.

The use of textile reinforcement holds an additional great advantage in the manufacturing of pre-cast concrete elements: markedly lighter and slimmer construction elements can be produced due to the position of the corrosion-resistant fibre materials directly under the surface of the concrete. As an example, concrete cladding panels in large dimensions of up to 120 cm x 240 cm and only 33 mm thick can be produced. These were first used on the façade of the Technical University in Dresden as 3D textile reinforced cladding panels Betoshell BIG from Hering Bau building contractors. The façade of the train station in Arnheim was also clad with it. In comparison: a cladding panel reinforced with steel of the same size would need to be at least 80 mm thick due to the danger of corrosion.

A wide variety of fibre materials can be used

The spacing between the two textile layers of the 3D textile reinforcement Sitgrid can be varied from 5 mm to a maximum of 20 mm – according to the individual requirements of the precast concrete element. The load carrying qualities are determined by the density and angle of the pile spacing threads. In this way all possible load carrying requirements can be met. It is also possible to alter the form. Also the thickness and density of the two textile layers can be adapted to match the stress on and shape of the construction element. A wide variety of fibre materials can be used in the reinforcement – from fibre glass to basalt or aramid or carbon fibres. The latter is distinguished by its extreme stability and strength. In addition, it is possible to equip the textile structure with sensors or heating elements thus giving the construction element increased functionality.

Furniture and artwork

There are a variety of design options with 3D reinforced concrete: one of the main applications is concrete cladding panels that are distinguished by their low net weight and thickness and their extremely high flexible, tensile and impact resistant strength. It is a great advantage for the energy efficient renovation of building façades since more insulation may be used with the thinner panels resulting in a façade of the same dimensions as the original one. Additional areas of application can be found in the architectural design of rooms and buildings in public, semi-public and private domains – from furnishings for municipal use, in parks and gardens as well as benches, stairways and balconies or even objects of art. Customized solutions for roofing and protection against the elements can be realized with 3D textile reinforced concrete.

The company V. Fraas GmbH with its world market leadership competence in the area of technical textiles offers 3D textiles as reinforcement, especially for the reinforcement of concrete. The three dimensional textiles by V. Fraas have been available on mass-produced panels since 2010. The subsidiary V. Fraas Solutions in Textile GmbH has succeeded in developing a production line where for the first time these 3D textile reinforcements in large dimensions can be manufactured. Panels in the dimensions of from 50 cm x 50 cm up to 2 m x 6 m have been available since April 2010. Using special CAD software to simulate and visualize the reinforcement it is possible to optimize the realization of individual projects.