Frima develops new bushhammer and embossing unit

Frima GmbH now offers a cost-effective solution for artificial aging of concrete blocks. The company based in

Emden (Germany) has developed two new techniques not requiring a strand and thus allowing working in a less complicated way than using conventional methods.

By using the Frima machine it is possible to treat coarse-grained (single-layer), rustic-style as well as fine-grained surfaces of paving blocks, slabs, palisades, curbstones and masonry blocks. The operating principle of the system is based on two counter-rotating shafts, which are furnished with special tools (similar to a milling machine), treating the surface of the blocks and stones. It is possible to change the intensity with the aid of various parameters. This unique technique is protected by a European patent.

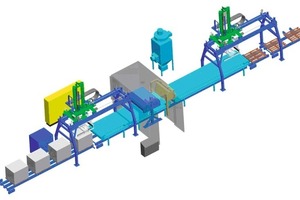

Up to now, the technique was only intended for offline operation. Owing to the fact that this method requires to set up a strand, it entails, however, high investment costs in total. In order to pass the unit (Fig. 1), it is necessary to set up a strand before embossing, which has to be separated again afterwards. Special handling systems are necessary especially for this purpose thus requiring associated production steps. The endless strand is used to protect the edges of the face and back side during processing ensuring a similar appearance of all products in this way.

This is the approach of the development of Frima. The technology of two new techniques enables to realize embossing in a much more cost-effective way. Here it is not necessary to set up a strand even without having to change the technique itself. Consequently, the plant becomes compact, uncomplicated and cost-effective.

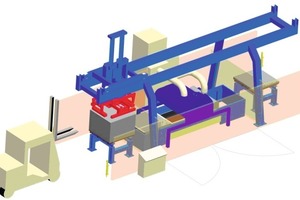

As to be able to meet the individual requests of the customers, one of the new techniques is still operating offline (Fig. 2). It comprises the embossing unit and a packaging unit carrying out both feeding and removal.

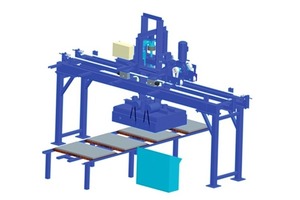

Another technique is operating online (Fig. 3) similar to the principle of a washing machine – however not on the fresh concrete side but on the dry side. The embossing process is directly integrated in the production line. Additional devices and production steps, such as setting up a strand, are eliminated. The compactness of the unit makes not only conventional embossing possible. This method allows the implementation of many other finishing techniques in a highly efficient way in one production step.