Mounting Parts in Design Software

Planning of transport anchor systems as well as connecting systems for precast concrete components has to be taken into account in a quite early stage of the project, because the precast concrete elements are generally not manufactured in their final position. Apart from dimensioning and the selection of the appropriate mounting parts it is, of course, also necessary to indicate such information properly in the corresponding plans so that the production process of the precast concrete components may run in the manufacturing shop without any misunderstandings and possible sources of error in due time.

Although the importance of an early planning is mandatory, this fact still is very often neglected - on the one hand, transport anchor systems are irrelevant for the static calculation of a building and, on the other hand, there is uncertainty and/or ignorance of the responsibilities for the security during transportation of a precast concrete element. However, the mentioned problem usually does not occurred in case of connecting systems, as they are more and more taken into account in the static verification of a building.

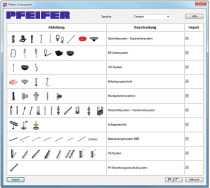

Irrespective of how important mounting parts are for precast concrete components, design and/or the drawing of the different elements constitutes a not inconsiderable part of the overall planning of a project. An effective CAD program, such as e.g. Allplan Precast of Nemetschek Engineering GmbH (www.nemetschek-engineering.at), that has especially been developed for precast concrete factories in combination with manufacturer-specific libraries of the mounting parts, clearly leads to an increase in efficiency. Up to about 50% time-saving may easily be achieved compared to creating one‘s own mounting parts, that is an unbeatable advantage when it comes to the nowadays usual tight schedules. The Philipp Group as a leading manufacturer of, among others, transport anchor systems and connecting systems for precast concrete components does not only guarantee the production and delivery of high-quality mounting parts but also provides the planner with comprehensive mounting part catalogs for design purposes. A further consequent step towards this direction is the collaboration with Nemetschek Engineering GmbH, who develops software programs especially for the precast concrete industry on the basis of Allplan, the leading construction-related CAD program, and is active around the world in this field. A comprehensive Philipp mounting part library is integrated as standard with the installation of the application Allplan Precast 2010 or can easily be updated respectively. A total of three different catalogs including the most important systems is available for the planner. This integration allowed to include the missing piece of the puzzle, transport and mounting systems, within the already quite extensive product range of mounting parts for precast concrete components available in Allplan Precast.

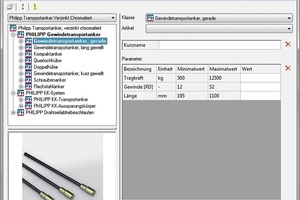

1.+ 2. Transport anchors made with zinc chromate coating and of stainless steel respectively

a. Threaded transport anchors

b. Spherical-head transport anchors

c. Cast-in lifting hoops (zinc chromate coating only)

3 . Connecting systems

a. Complete sandwich panel anchor systems (sleeve anchor, flat anchor and shear anchor)

b. Philipp Power Duo System

All three catalogs have a simple structure and can be used intuitively. Additional filtering functions, furthermore, make searching easier so as to find the right object very quickly. The mounting parts offered are part of the entire product range of Philipp and it goes without saying that they comply with state-of-the-art technology (Fig.1). Whether as a 3D body or as a projection in different viewing directions, every element is available in an appropriate way to meet the structural requirements. An automated evaluation of lists is a matter of course just alike the actual design, in order to determine the existing quantity of mounting parts and/or to serve as a basis for the producing factory for placing an order for the parts with the manufacturer.

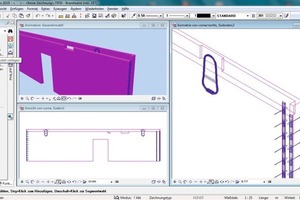

Here Philipp supports a consequent planning in 3D resulting in decisive economic advantages for engineering companies and precast concrete factories. Helpful functions of the application Allplan Precast, such as intelligent parts (iParts), animation, automatic drawing of element plans (including, among others, dimensional chains), automatically generated lists of mounting parts and assembly components with the aid of optimum data material of the PHILIPP mounting parts, are unbeatable means for an efficient planning of precast concrete elements (Fig. 2).

Philipp accompanied the user-days of Allplan Precast presented under the motto „Shaping the future. Utilizing strengths.“ held in several cities in Germany and Austria in November/December 2010, in order to showcase in public the new options provided by the Philipp catalog of mounting parts and to explain the most important details of dimensioning transport and mounting systems for precast concrete components. The high-flying response showed that an efficient planning of precast concrete components conducted with the appropriate tools will be more and more the key of success. For PHILIPP it also became clear that there is still some need for information when it comes to the subject of transport anchors and connecting systems, however planners are more and more aware of the need and importance of correct and early planning.

The Philipp GmbH consequently continued the already current efforts made by the company to simplify planning of transport and mounting systems and thus took also suggestions made in the direct dialog into account for designing adequate tools. Even tools customized for the planner - whether it are software-based or web-based tools and/or easy to understand print media - can make them forget quite quickly the image of transport anchor systems as a nuisance when designing precast concrete elements. In this connection, the incorporation of a mounting part catalog in the CAD design software represents the starting shot of further developments that are pointing the way ahead. Besides the direct contact to customers and interested people which is quite important for Philipp and always searched for also e.g. in lecture series, training courses or the like, they also focus on an active participation as a supplier of the precast concrete industry in various organizations representing the common interests of the industry.

Furthermore, with the catalog of mounting parts Philipp supports the approach of an integrated planning in the sense of optimized construction and cost management. Here the keyword is „Building Information Modeling“, BIM in short. The uniform digital building model is the core of the Building Information Modeling. Such building model does not only represent a spatial illustration of the building in a virtual world but also provides additional data about the properties of all building components and the relations to one another as well as the specific characteristics and properties of the building as a whole. The common three dimensions are thus complemented by another one representing the information of the building. The company is also actively participating in this part, pursuing high demands and collaborating with well-known manufacturers of CAD programs for the structural engineering and the precast concrete industry respectively.

Trade fairs such as BAU 2011 in Munich or BetonTage in Neu-Ulm are further platforms for Philipp to give an impression of a manufacturer of mounting parts for the precast concrete industry that is looking outside the box of a mere supplier.